Imagine the convenience of being able to fill a hydraulic system on the go, without the need for a bulky and expensive air compressor. Well, wonder no more, because a portable tire compressor might just be the solution you’ve been searching for. In this article, we will explore whether a portable tire compressor has the ability to effectively fill a hydraulic system, and the advantages it brings to the table. So if you’ve ever found yourself in need of a quick hydraulic system top-up while out and about, keep reading to find out more!

Understanding the Basics of a Portable Tire Compressor

Definition of a Portable Tire Compressor

A portable tire compressor, also known as a portable air compressor or simply a tire inflator, is a small and compact device that is designed to inflate the tires of vehicles. It is an essential tool for maintaining proper tire pressure, which ensures optimal performance, fuel efficiency, and safety on the road. Portable tire compressors have become increasingly popular due to their convenience and versatility, as they can be easily carried and used anywhere, making them an ideal choice for emergency situations or when regular access to conventional air compressors is not available.

How a Portable Tire Compressor Works

A portable tire compressor works by drawing air from the atmosphere and then compressing it to a higher pressure. It consists of a motor, a compression mechanism, and various control valves and gauges. When connected to a power source, such as a vehicle’s battery or a separate power outlet, the motor drives the compression mechanism, which compresses the air and stores it in a tank. The compressed air is then dispensed through a hose and nozzle, allowing the user to inflate the tires by simply attaching the nozzle to the tire valve.

Uses of a Portable Tire Compressor

The primary use of a portable tire compressor is to inflate vehicle tires. It is a handy tool to have in case of emergency situations, such as a flat tire, where immediate access to a gas station or service center may not be available. Regularly checking and maintaining the correct tire pressure is important for tire longevity, fuel efficiency, and overall vehicle performance. A portable tire compressor enables you to accomplish this task conveniently at your own convenience, without relying on external assistance.

Apart from inflating vehicle tires, a portable tire compressor can have other practical uses as well. It can be used to inflate bicycle tires, sports balls, and other inflatables. Additionally, it can also be used for small cleaning tasks, such as blowing away dust and debris from hard-to-reach areas in your vehicle or workspaces. The versatility of a portable tire compressor makes it a valuable tool to have in your arsenal, providing convenience and peace of mind in various situations.

Fundamentals of Hydraulic Systems

Definition of a Hydraulic System

A hydraulic system is a technology that utilizes the power of fluids to generate and transmit force. It is commonly used in various industrial and mechanical applications where a significant amount of power or force is required. Hydraulic systems are based on the principle of Pascal’s law, which states that when pressure is applied to a fluid in a confined space, it is transmitted equally in all directions. This principle allows hydraulic systems to transfer energy efficiently and precisely, making them suitable for a wide range of tasks.

Components of a Hydraulic System

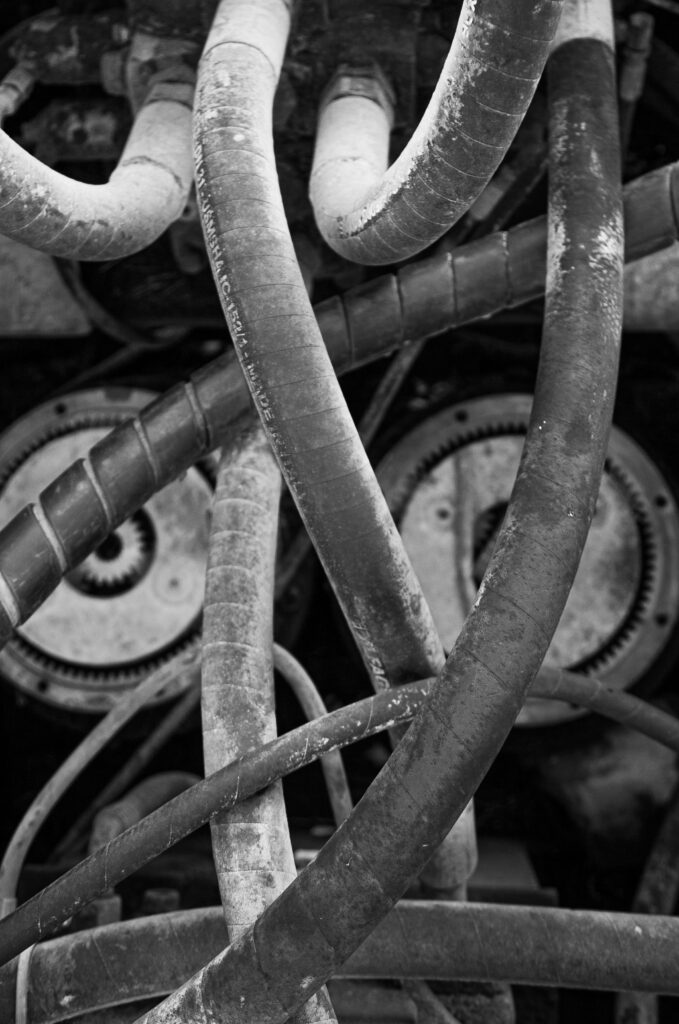

A hydraulic system consists of several essential components that work together to generate, control, and transmit hydraulic power. These components include a hydraulic fluid, a reservoir, a pump, valves, actuators, filters, and various interconnecting pipes and hoses. The hydraulic fluid acts as the medium for transmitting power and pressure within the system. The reservoir stores the hydraulic fluid and helps to dissipate heat generated during operation. The pump is responsible for pressurizing and circulating the hydraulic fluid, while valves control the flow and direction of the fluid. Actuators, such as hydraulic cylinders and motors, convert hydraulic pressure into mechanical force or motion. Filters are used to remove contaminants from the hydraulic fluid, ensuring the system’s reliability and longevity.

Working Principle of a Hydraulic System

The working principle of a hydraulic system involves the conversion of mechanical force into hydraulic pressure, which is then transmitted through the fluid to perform work. When a force is applied to an actuator, such as a hydraulic cylinder, it displaces the hydraulic fluid within the system. This displacement creates pressure in the fluid, which is transmitted to other parts of the system through pipes and hoses. The hydraulic pressure can be controlled and directed by opening or closing valves, allowing the system to perform specific tasks, such as lifting heavy loads, moving machinery, or applying precise force. The working principle of a hydraulic system is highly efficient and reliable, making it a preferred choice in numerous industrial applications.

Can a Portable Tire Compressor Fill a Hydraulic System?

Analyzing the Possibility

While a portable tire compressor and a hydraulic system both involve the compression and use of fluids, they are fundamentally different in terms of their design, components, and operating principles. As such, it is not recommended to use a portable tire compressor to fill a hydraulic system. The components and operating pressures of a tire compressor are not designed to handle the demands of a hydraulic system, and attempting to do so may result in potential damage or failure.

Challenges in Using a Tire Compressor for a Hydraulic System

There are several challenges in using a portable tire compressor for a hydraulic system. Firstly, the operating pressures of a hydraulic system are typically much higher than those of a tire compressor. A typical tire compressor operates at pressures between 80-150 psi, whereas hydraulic systems can operate at pressures exceeding 3000 psi or more. The components and seals of a tire compressor may not be able to withstand such high pressures, leading to leaks, failures, or even ruptures.

Another challenge is the suitability of the fluid used. Tire compressors use air as the working medium, while hydraulic systems utilize hydraulic fluids, such as oil or synthetic fluids. The properties and characteristics of hydraulic fluids are specifically formulated to meet the requirements of hydraulic systems, including lubrication, sealing, heat dissipation, and compatibility with system materials. Using air instead of hydraulic fluid in a hydraulic system can lead to inadequate lubrication, increased friction, and potential damage to the system’s components.

Potential Risks and Damage

Attempting to fill a hydraulic system using a tire compressor can pose several risks and potential damage. The insufficient operating pressures of a tire compressor may not allow the hydraulic system to function properly, leading to reduced efficiency and performance. Moreover, the use of air instead of hydraulic fluid can cause increased friction and wear on the system’s components, potentially leading to premature failure or breakdown. The potential risks and damage associated with using a tire compressor for a hydraulic system make it strongly advised against doing so.

Differences between Air Compressors and Hydraulic Systems

Operating Principle of Air Compressors and Hydraulic Systems

The operating principles of air compressors and hydraulic systems are fundamentally different. Air compressors work by compressing and pressurizing atmospheric air, which is then used as a source of energy. On the other hand, hydraulic systems utilize hydraulic fluids, such as oil, which are incompressible and transmit pressure from one point to another to perform work. The difference in operating principles results in varying characteristics and capabilities of each system.

Nature of Fluids Used

Air compressors use atmospheric air as their working medium. Air is readily available, free, and easy to handle. However, air is compressible, which means it can be compressed or expanded based on the application requirements. Hydraulic systems, on the other hand, use hydraulic fluids, such as oil or synthetic fluids. Hydraulic fluids are incompressible, which allows them to transfer pressure efficiently and precisely. The use of hydraulic fluids also provides additional benefits, such as lubrication, cooling, and protection against corrosion.

Pressure and Volume Characteristics

Air compressors typically operate at lower pressures compared to hydraulic systems. The operating pressures of air compressors typically range from 80-150 psi, while hydraulic systems can operate at pressures exceeding 3000 psi or more. Similarly, the volume or flow rate of air from an air compressor is generally higher compared to the volume of hydraulic fluid. Hydraulic systems are designed to operate with lower flow rates but higher pressures, providing precise control and power.

The differences in pressure and volume characteristics between air compressors and hydraulic systems make them suitable for different applications. Air compressors are commonly used for tasks such as inflating tires, powering pneumatic tools, and supplying air to machinery. Hydraulic systems, on the other hand, are used for applications that require precise control of force, speed, or position, such as heavy machinery, construction equipment, and automotive braking systems.

Professional Opinions on Using Portable Tire Compressors for Hydraulic Systems

Expert Take on the Matter

Experts strongly advise against using portable tire compressors for hydraulic systems. The operating pressures and components of a tire compressor are not designed or rated to handle the demands of a hydraulic system. The risks of using a tire compressor for a hydraulic system, such as leaks, failures, or damage to components, far outweigh any potential benefits.

Case Studies

Several case studies have documented the negative consequences of using a portable tire compressor for hydraulic systems. In one instance, a hydraulic system used in a manufacturing plant was filled using a tire compressor due to the unavailability of a suitable hydraulic pump. The lower operating pressures of the tire compressor resulted in reduced system performance and frequent breakdowns, leading to significant downtime and increased maintenance costs. The case study highlighted the importance of using the proper equipment for hydraulic systems to ensure reliability and operational efficiency.

Precautions to Take

To avoid any potential risks or damage, it is crucial to follow industry standards and guidelines when working with hydraulic systems. Always use the recommended equipment, such as hydraulic pumps or power units, for filling or maintaining hydraulic systems. Regularly inspect and maintain the system according to manufacturer specifications to ensure proper functioning and safety. It is also advisable to consult with hydraulic system experts or professionals for any concerns or questions regarding hydraulic system maintenance or operation.

Potential Alternatives to Portable Tire Compressors

Hydraulic Pumps

Hydraulic pumps are specifically designed to generate the high pressures required for hydraulic systems. They come in various types, such as gear pumps, vane pumps, piston pumps, and axial piston pumps, each suited to different applications. Hydraulic pumps provide reliable and efficient performance, ensuring that hydraulic systems operate at their optimal levels.

Hydraulic Power Units

Hydraulic power units, also known as power packs, are complete hydraulic systems that consist of a hydraulic pump, a reservoir, valves, and other necessary components. They are self-contained units that can be easily transported and provide the required hydraulic power for various applications. Hydraulic power units are an excellent alternative to portable tire compressors for filling hydraulic systems, as they are specifically designed for this purpose.

Hydraulic Compressors

Hydraulic compressors, sometimes referred to as gas boosters, are used for increasing the pressure of gases or compressed air when higher pressures are required. While they may have overlapping applications with portable tire compressors, hydraulic compressors are designed and built to handle higher pressures and specific types of gases or compressed air. They are not suitable for filling hydraulic systems, as they lack the necessary components and features required for hydraulic fluid transmission.

Consequences of Using the Wrong Equipment on Hydraulic Systems

Damage to System Components

Using the wrong equipment, such as a portable tire compressor, for hydraulic systems can lead to significant damage to system components. Components designed for lower operating pressures may fail or rupture when exposed to the higher pressures required by hydraulic systems. Leaks can occur, leading to loss of hydraulic fluid and potential contamination. The resulting damage can affect the system’s performance, efficiency, and even compromise the safety of personnel operating the equipment.

Safety Risks

Using the wrong equipment on hydraulic systems can pose serious safety risks. The failure of system components due to inadequate pressure handling capabilities can have catastrophic consequences. High-pressure hydraulic fluid leaks can cause severe injuries to personnel, damage surrounding equipment, and create hazardous environments. In addition, the use of inappropriate fluids can compromise the system’s overall safety, as fluid properties play a crucial role in controlling system temperature, viscosity, and operating efficiency.

Increased Maintenance Costs

Using the wrong equipment on hydraulic systems can result in increased maintenance costs. Premature component failures, frequent breakdowns, and system inefficiencies due to inadequate or improper equipment can lead to higher repair and replacement expenditures. Inefficient or ineffective equipment can also result in downtime and productivity losses, impacting overall operational costs. Regular maintenance and inspections become crucial to identify and rectify any issues arising from the use of inappropriate equipment.

Final Evaluation of Using Portable Tire Compressors in Hydraulic Systems

Weighing the Pros and Cons

After evaluating the differences between portable tire compressors and hydraulic systems, as well as considering expert opinions and case studies, it becomes clear that using a tire compressor for a hydraulic system is not advisable. While portable tire compressors offer convenience and are well-suited for inflating vehicle tires and other minor tasks, their operating pressures, components, and design do not meet the requirements of hydraulic systems. The potential risks, damage, and safety hazards associated with attempting to use a tire compressor for a hydraulic system outweigh any potential benefits.

Industry Standards

Ensuring compliance with industry standards and guidelines is vital when working with hydraulic systems. Various organizations, such as the International Organization for Standardization (ISO) and the National Fluid Power Association (NFPA), have established standards and specifications for hydraulic systems’ design, operation, and safety. Adhering to these standards helps ensure the optimal performance, reliability, and safety of hydraulic systems.

Practical Implications

The practical implications of using proper equipment for hydraulic systems are crucial. Using hydraulic pumps, power units, or compressors designed specifically for hydraulic applications ensures optimal system performance, longevity, and safety. Regular maintenance, inspections, and following manufacturer recommendations help identify and address any potential issues before they become significant problems. By using the right equipment and maintaining hydraulic systems in accordance with industry standards, the overall efficiency, reliability, and safety of these systems can be maximized.